Shellac is one of the premium wood finishes that impart richness to the wood and help in accentuating the natural attractiveness of distinctive wood grains. A diverse and durable finish, shellac over mineral oil, can be used to polish wooden surfaces, and it also works as an effective wood sealer. Shellac finishes are quite popular, and they are among the top recommended solutions for finishing both modern and classic wooden floors and furniture.

It is possible to apply shellac over mineral oil to produce amazing creations. We’ve run extensive experiments and presented a few application methods to guarantee fantastic finishes. Read on to learn how to apply shellac over mineral oil correctly.

Mixing mineral oil and shellac

This technique involves mixing the shellac and mineral oil in a 75% to 25% ratio. The oil component allows for smooth application without noticeable drag or lap marks. Hence, this method is perfect for applying with a rag or cloth, like padding.

A shellac-mineral oil mixture is different from a varnish-oil finish as it tends to require more coats to get a thick finish. You will need lots of time and effort to use this technique. Alternatively, you can save time by opting to brush several coats of shellac first and then add the shellac-mineral oil mixture as the last two or three coats.

Here is a breakdown of the process:

- Brush a few coats of shellac to the piece to create the necessary thickness

- Once you have completed the desired build, proceed to the sanding stage to get rid of brush marks

- You are now ready to apply at least two coats of the shellac – mineral oil mixture

- Let it rest for at least 24 hours and then wipe any oil off the surface using naphtha

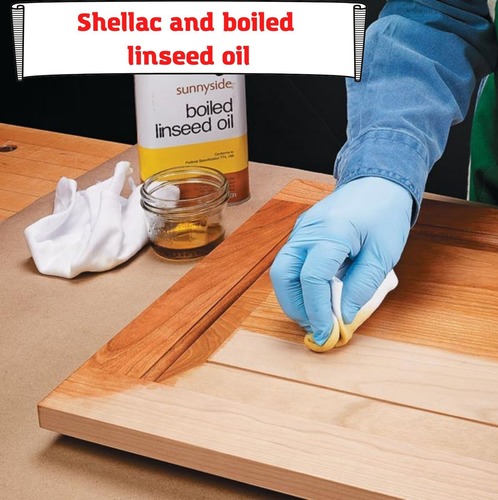

Shellac and boiled linseed oil

Another great alternative is to use a combination of shellac and boiled linseed oil. Linseed oil can saturate deep inside the wood, and it offers protection against humidity changes and scratches. It is eco-friendly, easy to apply and maintain, and delivers a distinctive satin look that accentuates the wood grain and color.

Here is a step by step process to follow when applying shellac and boiled linseed oil:

- Start by wiping the surface and then applying generous amounts of the boiled linseed oil.

- Let the wood rest for a short time, but not completely.

- Add calcium carbonate, china clay, or powder fillers in a pad and rub it on the wood until it cannot absorb more filler.

- Use a cloth to rub and polish the wood to create an attractive glow.

- At this point, the wood should be pretty smooth and ready for your desired topcoat, which will be a few layers of shellac for this process.

Spraying shellac over mineral oil

Spraying shellac over mineral oil offers the most straightforward and most convenient application method. It is ideal for intricate woodworking projects where using the traditional brushing application would be more challenging. Instead, you can spray on several light coats using a shellac aerosol can or HVLP gun instead of a single heavy coat.

The advantage of spraying shellac over mineral oil is that you are guaranteed much smoother finishes than brushing and padding. That is because the spray application does not agitate the wood grain. It also means minor sanding is necessary afterward, thus allowing you to complete the project within a shorter time.

Here is how to spray shellac over mineral oil:

- Prepare the surface by cleaning, sanding, and then wet rubbing against the wood grain with steel wool

- Prepare your de-waxed shellac and denatured alcohol mixture and allow it to rest for at least one day before application

- Using an HVLP gun, spray at least three coats on the surface of the wood and let it harden overnight

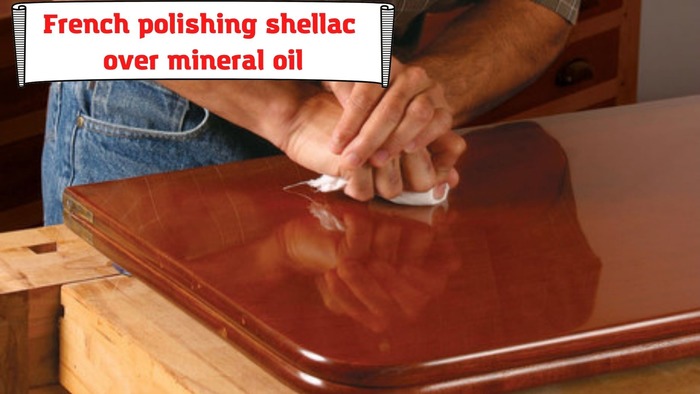

French polishing shellac over mineral oil

French polish is a unique shellac application method that creates a nearly glass-like finish with fantastic depth. This technique is responsible for the extraordinarily glossy finishes found on antique wooden furniture and wooden instruments like violins and guitars.

Even though it has been widely used since the 16th century, French polish is not very popular nowadays because it is pretty labor-intensive. In addition, it takes practice and time to master this skill effectively.

Here’s how to apply shellac over mineral oil using the French polish method:

- The first step is to sand the wood and eliminate old finishes, varnish, rough surfaces, or paint

- Buy prepared shellac or mix your shellac by adding denatured alcohol

- Make a customized golf-ball-size dabber with cotton balls, wool, or cotton placed inside a piece of small cotton fabric.

- Apply some olive to the dabber to help lubricate and support smoother movements on the wood

- Begin with your first sealer coats of shellac and use even, sweeping strokes across the wood

- Use pumice powder to fill in any open wood grain with firm, circular motions

- Continue adding more shellac using the dabbing pad, ensuring even, thin applications

- Dab some denatured alcohol onto the wood to eliminate excess oil

Repeat all the steps above as necessary until you get the glossy final finish. You will need at least seven or more repetitions for great results. Once the shellac dries completely, you can protect the glassy look by buffing it with wax furniture polish.

Essential tips to know when applying shellac over mineral oil

There are several things to consider when using shellac finishes over mineral oil. A key consideration is that any substance with alcohol, like cologne or liquor, can affect the final finish. In addition, other chemicals, such as ammonia, may cause issues, so you must be keen on how you clean the shellac finish.

Excessive heat can soften the shellac coating. So, it is recommended to avoid using hot items on shellac surfaces, like hot pans. That way, you can preserve the hard finish for a more extended period.

Another point to note is that shellac isn’t a water-resistant coating. That means it is not appropriate for application in bathrooms or kitchens. Watermarks or humidity will give your shellac finish an unappealing whitish tone.

Shellac also tends to show lap marks or brush strokes easily. If you plan to apply shellac using a cloth or rag, you may experience drag if you’re not quick enough. Since using a brush or a fabric may not deliver the smoothest finish over mineral oil, sometimes it is best to consider spraying shellac.

The other notable fact about shellac is that it dries significantly fast and even faster after adding denatured alcohol. This fast drying time is both a benefit and a disadvantage. It means you can apply multiple shellac coats within the same day and finish your project quickly. However, the downside of the fast drying time is that you must work very quickly to guarantee a good and even coat.

Remember that you aren’t building up new layers as you apply shellac. That is because each next coat will always melt and bond into the last layer. What is remarkable about this fact is that if you have a drip or a run, you can sand it away before applying more shellac to create an even surface again.

Precautions when applying shellac over mineral oil

Be careful when handling and disposing of the rags used for applying the shellac coatings over mineral oil. Even though shellac is entirely safe and non-toxic, the alcohol content required for dissolving it is exceedingly flammable. Moreover, even the vapor produced when shellac is drying is highly volatile and dangerous.

Hence, if you used a rag application method, you should allow sufficient time to effectively dry the fabric on a safe, non-flammable area like concrete or soaked or washed with water before placing it inside your garbage bin.

It is also recommended to wear safety equipment like a dust mask when applying shellac, especially when sanding between different coats. The fine dust from sanding can often cause multiple health issues, and it is essential to protect yourself.

Conclusion

Shellac finishes are versatile, easy to apply, and often boast of high compatibility, ensuring that they adhere to different base coats. Provided you do a bit of sanding before application, shellac over mineral oil can suit a wide range of projects, from fine furniture to wood floors and others. Moreover, shellac supports different application methods, ranging from brushing and padding to spraying and more intensive methods like French polishing.

The optimal number of shellac coats over mineral oil is at least three to four layers, with the necessary sanding in between. You can add more coats if you haven’t achieved the desired effect yet. For the last coat of shellac, try and make it as thin and smooth as possible to get the best results. Additionally, ensure the brushing or padding goes with the wood grain and not against it.

Overall, shellac works great as a woodworking finish that can enhance the wood’s natural grain and add remarkable smoothness without producing the unwanted plastic-looking effects of lacquer or polyurethane. It is readily available, applies quickly, and also dries considerably quickly.

- Shellac Over Mineral Oil – Possible? We’ve Conducted Experiments - January 29, 2022

- Mixing Primer with Texture. And Some Mistakes You Might Make - January 28, 2022

- Acrylic Enamel Reducer Substitute. Safe Testing And Proper Application - January 22, 2022