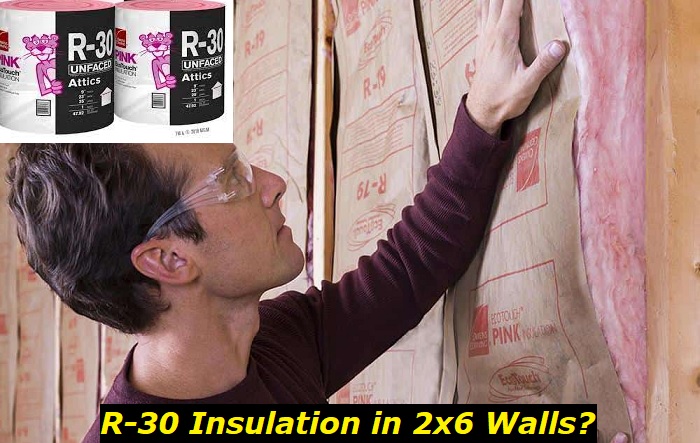

Wall insulation is a standard practice in buildings, and you cannot afford to take chances. Insulation should accommodate different climatic conditions and temperatures all in one. Despite having an idea of how to insulate walls, many do not know whether R-30 in Insulation would work well in 2×6 walls.

Professionals who work by the guidebook also have differing stands regarding this type of Insulation. The higher the R-value, the better the heat flow. However, there are limitations and further guidelines to that rule.

We will look at a few insulation guidelines below that you should follow when working on a 2×6 wall:

- Why do you need to insulate

- Which walls work well with R-30 Insulation?

- Types of insulation material to use

- Is R-30 ideal for your walls

- Alternatives when R-30 is not applicable

- Benefits of R-30 Insulation to your wall

- Problems that you can expect from the R-30 wall insulation option

Why Insulate?

1) Thermal Control and Efficiency

Insulating a house prevents the effects of extreme weather. Extreme winters will leave you cold and, in extreme cases, give you frostbite. In extremely hot summers, the heat can be unbearable and even ruin products in your home. Insulation is that barrier between all extremities. It helps reduce heat loss during winter and absorption of the same during summer.

Global warming has also pushed the temperatures over and above normal ranges. This new normal requires you to create a haven where you are fully protected from these effects. To help control temperatures, heating and cooling spaces using air conditioners is getting discouraged. This means alternative and safe options that do not strain the resources more than necessary.

2) Sound Proof

Silence is golden, and nothing is more irritating than listening to noise and conversations you are not privy to. Creating a barrier that locks all that sound out can bring the desired peace into your life. While at it, you must ensure you can keep your noise and conversations within. Being mindful of others around you is an underrated effort. Homeowners insulate shared walls to keep one home’s noise away from the rest by insulating party walls.

Having people all over your business can be quite a bummer. The Insulation might not keep all the noise out, but it keeps most of it out. With kids and toddlers, this might be all you need to have them sleep through their planned schedules. Lack of proper sleep affects their growth and keeps them grumpy. It is also a distraction when working or studying from home.

3) Building Requirements

Before a home or a building can be considered fit for occupation, it must meet all building standards. One of these standards includes Insulation. The international energy conservation code updates insulation standards after three years. In the US, Insulation became mandatory after the oil crisis. The crisis left most homes damp and extremely cold. Part of the incentive offered by governments includes tax credits on efficient upgrades.

Most homes previously sealed walls, but overall Insulation in the units is key to heat efficiency and preventing the stack effect. This effect forces warm air to rise while cold air occupies the vacuum left. The cycle forces condensation and a cooling effect that is detrimental to skyscrapers. Lower floors become extremely cold and form mold. In homes, this effect forces many to keep their doors locked, ruining air quality.

Types of Insulation Options

1) Batt Insulation

Also known as blanket insulation, it comes in the form of batts and rolls. The batts are made from flexible fibers that are compressed and reinforced to form a roll. The most common batts are those made from fiberglass. However, many other options exist, such as mineral wool, natural, and plastic fibers.

From manufacturers, you can get precut options whose R-value ranges between R-19 and R-21. You must cut and add more layers to ensure it meets your R-30 specifications. The panels are fitted within studs and beams in 2×6 walls. Where stuffed, the excess material is cut to ensure the wall remains flattened. Some come with facings while others do not. The facings help increase the air and vapor barrier. As a bonus, some come with heat-resistant properties, which helps improve Insulation further.

2) Loose Fills and Blown in Insulation

This type of Insulation consists of a mixture of loose particles that are either blown in or poured into the spaces needed. Seek the services of a professional when making the compaction. Their know-how in that field helps you achieve the correct density, weight, and thermal regulations expected. They are ideal for all spaces since they easily conform. This feature makes it ideal when working in closed-up spaces.

The particles can be from one product or a mixture of recycled products. When one product is used, it is easy to determine the R-Value. However, a lot more is needed when different types of particles are used.

Different materials offer a varying range when it comes to heat flow. It is the manufacturer’s responsibility to determine the R-value in each composition. Using that information, you can tweak it to your specifications. Be careful when purchasing this product, as some manufacturers offer false information.

3) Rigid Fiber Boards

They are a perfect fit for air ducts and spaces that can withstand heat. The boards are produced either at our site or the factory. Once done, they are screwed in using special screws and pins. They are then subjected to heat through a welding machine. It is impaled using the pins to secure them.

When using unfaced boards, you need to factor in cement mastic or other sealing options you plan to use. Ensure they are compatible to avoid future problems such as sweaty walls, rotting, and stains. Faced boards make work easier as all you need is mastic or tape to hold the joint edges together. The R-value is determined long before installation through its thickness ranges of between 1 to 2.5 inches.

4) Concrete Blocks

This type of Insulation incorporates its insulation capabilities within the structural unit. The concrete blocks come pre-fabricated and are easy to install, nail, and even carry around due to their lightweight. It comes in two forms of precast masonry units, Autoclaved Aerated Concrete (AAC) and Autoclaved Cellular Concrete (ACC). These units contain woodchips, Fly Ash, and polystyrene beads as insulation materials.

Others are manufactured to take on Insulation once installed when such insulation materials do not meet the R-Value standards. Since they can be fabricated, you can easily raise the R-Value. To do this, you must manipulate the insulation material composition or insulate the cores. Some prefer exterior wall insulation to ensure it traps the air levels maintained inside. The downside to this insulation option is that the concrete panels absorb water, and you need to find a sealant first.

ICF

Insulating concrete forms are formed through interconnecting hollow foam blocks. They are secured using ties from plastic material to avoid corrosion and rotting. Once safely secured, steel or iron rods are inserted to reinforce and increase the strength of the walls.

Concrete is then poured and allowed to mix with the insulating material. Cons derived by most from this process include water and insect damage. Manufacturers now treat the blocks before installation to prevent insects and offer education on how to avoid water damage.

Foam Boards

Also known as rigid boards, they are an effective option when working with tight spaces. They offer twice or even more thermal resistance than other boards with the same thickness. They are made from polystyrene or polyurethane. They are also poor heat conductors, which lowers the heat loss through heat conductors such as steel and wood. They also help minimize eating into a unit’s square footage due to their efficiency per inch.

Sprayed Foams

They come in a liquid form, making it easy to spray, inject, or pour on the surfaces. They can also be blown in closed spaces or formed if necessary. Since they contain tiny particles, they are perfect for small spaces such as cavities, cracks, and cable penetration points. You can use the closed-cell foam that is slightly dense or the open-cell foam that is lighter.

Before using the closed cell foam, you need special gadgets and gas. The gas, when mixed with the foam, makes it expand. The expansion makes it appear spongy. The light open cell form should be used above ground to avoid absorbing water. Since it can be bought in spray cans, you can easily use it to seal windows, doorframes, or even cracks.

Conclusion

In summary, R-30 is a suitable insulation option for 2×6 walls. Some materials will never get you to this value, while others only require a slight adjustment. Furthermore, it takes more than an R-Value to get your house the Insulation needed.

You might use the right material and fail to hit the targeted range. This is because other factors contribute to this overall R-value. Professional guidance is necessary when such values are in question and when in doubt. You might save yourself a whole lot.

- Can You Unmix Paint: Techniques, Consequences, Alternatives - February 23, 2024

- Does Primer Need to be Mixed? Effective Primer Application - February 22, 2024

- How to Make Old Paint Usable Again: Retrieving and Preserving Paint - February 21, 2024