It is widely implicit that paints must be sprayed on completely rust-free and other contamination-free surfaces to provide the highest level of protection. It is particularly true for contemporary high-performance coatings such as epoxies and inorganic zinc silicates, where high-quality abrasive blasting is frequently required.

However, due to design, cost, safety, or other considerations, there are some instances when it is not feasible to eliminate all corrosion from the surface. To eliminate the necessity for such crucial surface repairs, there has been immense research into solutions for corroded surface preparation.

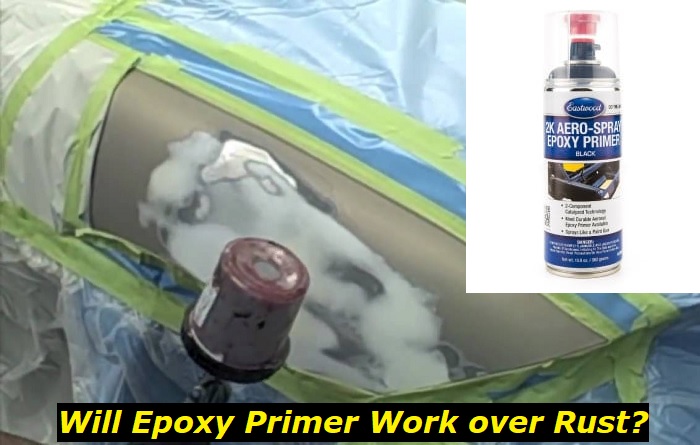

Although it is typically not necessary, many items have emerged on the market for these uses. However, the question is – is applying epoxy primer over rust possible? How does one go about it? There are numerous aspects in play, and here is what we are going to cover:

- Debunking epoxy primers

- The various applications of epoxy primers

- The use of epoxy primers on rusty surfaces

- Eliminating rust on surfaces before using epoxy primers

- The reasons why regular body primer is prone to rust

Epoxy Primers Described

An epoxy primer is a sealant that gives sprayed topcoats a high surface finish. Epoxy primers are used in waterproofing materials, which subsequently guard against oxidation of bare metals.

Zinc phosphate, which is a pigment that functions to inhibit or prevent corrosion, is a component in a two-part epoxy primer. Before using the two-part epoxy primer, it must be well mixed, and a dry and extremely clean surface is required.

The word “epoxy” also relates to epoxy resins that often form after the material cures. It is a chemical reaction in which a substance hardens from exposure to oxygen, heating, or chemical additives. The accelerator in epoxy, which functions as a chemical ingredient to speed up a chemical process, aids in curing.

The outcome is an exothermic process that causes a cross-linkage within the polymer. The stiffness and strength of epoxy materials are due to the ensuing cross-linkage.

What are the Uses of Epoxy Primers?

If someone wants to reap all of its advantages, they must be cautious about what they apply it to. Below is some information on the uses of epoxy primer.

1) Over Bare Metal

Epoxy primers are fantastic at sealing up exposed metal and preventing rust or moisture infiltration. The epoxy primer separates the metal from the air, humidity, chemicals, and UV radiation.

Unlike other inexpensive spray-bomb primers, it prevents the risk of corrosion developing on surfaces; it is the only bare metal primer one can leave a car outside in without corrosion or rust forming. Zinc phosphate is added to two-part epoxy primers, enhancing their corrosion-inhibiting capabilities.

Simply put, epoxy is the ideal primer for bare metal. Hence, it is perfect for freshly produced or completely stripped metal parts.

2) Mixed Surfaces

Certain primers and coatings require a homogeneous surface made of the same material throughout. Epoxy primers attach to bare metal, painted surfaces, and fillers thanks to their exceptional adhesive capabilities.

It implies that someone can apply epoxy primer to a spot that has been patched up with body filler, sandblasted to bare metal, and then sprayed into the original paint.

3) On Metal Imperfections

Epoxy primer not only has excellent adhesion and bonding properties, but a high-build recipe also fills in minor flaws in the metal. Because of its incredible adhesive qualities, it can seal minor fractures and dents.

Epoxy primer will assist in smoothing out any little bumps or fissures remaining after sanding when someone has applied body filler to a certain region.

4) Layering Coatings

Epoxy primers stick mechanically; thus, they will cling to almost anything with decent surface roughness. As a result, stacking works nicely if someone needs to rectify an area that they did not get completely flat and requires a little additional filler.

One can use sandpaper to scuff, apply filler, sand flat, and then feather the edges. Finally, they can apply more epoxy primer on top after that and repeat as necessary.

5) Protect a Long-Term Project

Not everybody has a sizable, climate-controlled shop where they can store their project cars while they are being painted. It means that one might have to leave their project outside during the night or as they maintain their daily driver.

Perhaps the shop is humid and metal flash-rusts whenever the weather changes. After the day, it is best to use an epoxy primer to protect the work. It will prevent them from returning to a rusted-out disaster if they cannot finish it right away. One must lightly scuff sand a car before painting it if they allow the epoxy primer to rest on it for up to five days.

One should have a few epoxy primer cans for small-area sealing. Compared to bringing out the spray gun, preparing the priming, and then having to clean everything back up, they will save you time.

6) Use it for a Final Sealer

People have been using an epoxy primer as a finishing sealant before their base coat, which is a neat technique. One simply cuts it in half and applies one or two coats to finish sealing all of their work and provide a smooth surface for their base coat to sit on.

The primer will prevent actual paint from peeling or flaking and provides great adherence to the majority of topcoats. It is excellent comfort for a long-lasting paint job.

Using Epoxy Primer Over Rust, is it Possible?

Epoxy primers have the ability to waterproof surfaces, which subsequently guards against oxidation of the bare metal. Using one should use a wire brush to remove surface flakes and powder from partially rusted metal parts before priming with a rust-inhibiting primer.

One can utilize an electric drill with a flap wheel or sanding disc to work faster on extreme rust. After that, the rust can be painted over. However, some rusty surfaces will need more work done before priming and painting.

Rust will not form on the steel due to the epoxy itself as long as it is sufficiently thick. A layer of epoxy that is too thin will eventually allow oxygen and moisture to penetrate the steel, just like other coatings do; over time, no polymer can inhibit corrosion.

Eliminating Rust Before Painting

Steel exposed to moist air rusts within a few days. Rust would spread under the paint if there were some rust on it when it was painted. Before applying primer and paint, car manufacturers treat the exterior shells of their vehicles by blasting them with a phosphoric acid solution, which is then completely rinsed off.

Most commercially available rust inhibitors have an acidic base. There are two kinds: rust-removal fluids and primer paints that resist rust. The acid employed is typically phosphoric, but it can also be hydrochloric or tannic.

Before using Epoxy Primer and painting the treated area, one should apply the fluid, let it sit for a predetermined amount of time, clean it off, properly rinse with clean water, and let it dry completely.

Some removers come in jelly form to avoid dripping on good paintwork that would be harmed by the acid’s corrosiveness. If someone does spill such a liquid on their skin, paintwork, or anything else, they should wash it off right away with lots of water.

Rust-resistant primers like Epoxy Primer work in a less pronounced manner. Before utilizing them, the manufacturers advise people to remove most of the loose rust. One applies the primer and gives it a certain amount of time to work.

When used on non-rusty surfaces, some types of primers do not dry completely; one must clear off the excess.

Why Is Regular Body Primer Prone to Rusting?

Regular body primers might cause significant issues for DIY people. Since it is porous, it will not shield the surface from the moisture and oxygen mixture that causes corrosion. Its function is not to give anti-corrosion protection but rather to act as a form of cross-linking agent between the surface and topcoat.

As a result, car body panels may begin to rust within seven days of being primed. It also applies to single-pack aerosol primers, which frequently have pores. Professional car body shops do not have an issue with this because they usually apply the topcoat shortly after the primer. They avoid this by minimizing the time spent applying topcoat and primer.

Final words

In sum, steel exposed to moist air rusts within a few minutes. Rust will spread beneath the paint if someone paints over the rust. Epoxy primer is an excellent sealant used to waterproof surfaces, protecting them from developing rust as well as giving the top coat a great finished look.

Epoxy primers help protect a long-term project from the elements, especially moisture that can lead to rusting and subsequent delays. Epoxy primers are also appropriate for “mixed surfaces,” which are panels that contain both bare metal and painted regions.

However, you should make every effort to blend these areas evenly. You can use epoxy primers on rusty surfaces after removing the rust using a wire brush or, in extreme cases powered brush.

- Can You Unmix Paint: Techniques, Consequences, Alternatives - February 23, 2024

- Does Primer Need to be Mixed? Effective Primer Application - February 22, 2024

- How to Make Old Paint Usable Again: Retrieving and Preserving Paint - February 21, 2024