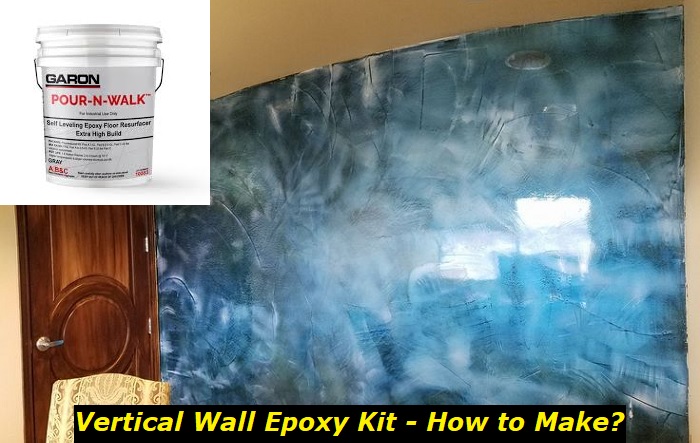

Using epoxy on your wall sounded like a good idea. That is, until it started dripping down to the floor. And although you tried to remove the drips, they have already hardened. Odds are you used the wrong technique. So what went wrong?

We’ll answer the following questions in this article:

- What is epoxy

- Why is epoxy hard to apply to vertical surfaces?

- What tools do you need to apply epoxy to a vertical surface?

- How can you apply epoxy to a wall?

What is epoxy?

Epoxy is a type of synthetic polymer. It consists of many epoxide subunits linked together chemically. These subunits become cross-linked after a chemical reaction, which leads to the formation of a hard epoxy resin.

Like most synthetic polymers, epoxy has many benefits. First, it’s very durable. Once it hardens on a surface, it can withstand physical elements for years to come. Epoxy is resistant not only to mechanical damage but also to high temperatures.

Moreover, epoxy coats are much more affordable compared to other alternatives. The materials needed for the manufacture are easy to come by, which means about anyone can afford it.

Another advantage of using epoxy is that it self-levels. The liquid spreads evenly across a surface as you apply it, resulting in a smooth finish. This makes it an excellent choice even for beginners.

However, the self-leveling nature of epoxy can work against you if you’re dealing with vertical surfaces.

Applying epoxy to a wall – what to look out for?

Epoxy spreads out across the surface evenly, ensuring a smooth finish. This is because of surface tension. But while this is great for painting floors, it makes painting vertical surfaces much harder.

The epoxy resin will drip down the wall as you apply it, resulting in an uneven finish. Since the polymer dries fast, your wall may end up being covered in hardened drops. These are then incredibly difficult to remove. In most cases, you can’t fix this unless you completely remove the coat.

To prevent this, you must change your application technique. We recommend applying epoxy in several thin layers rather than in a single thick one. Allow each layer to dry before you move on to the next one.

The only time you want to apply a thick layer is if you’re the wall has many holes or dents. In this case, you can use a thicker coat to even it out. However, you must smoothen each drip as it appears to prevent bloating. Even so, you’re probably better off using a primer first.

What do you need to apply epoxy to a vertical surface?

1) Foam roller

Although you have several options when it comes to tools, we achieved most of our best work using a foam roller. It allows you to apply the epoxy in thin, even layers, resulting in fewer drips.

The better control also prevents you from pressing too hard onto the surface. Doing so can result in ‘dry patches’ with very little epoxy. While you can fix these later, it can get very time-consuming.

Moreover, we recommend staying away from brushes. They are way too unwieldy and apply epoxy very unevenly. You’ll also have a much harder time smoothening out imperfections with them.

As far as size is concerned, it depends on what surface you’re dealing with. Bigger rollers are generally better if you have a lot of area to cover. However, keep in mind that bigger rollers are harder to control. Not to mention they will tire your arm faster.

2) Primer

Although the primer is not mandatory for epoxy application, we strongly recommend buying one. Applying epoxy without a primer often results in an uneven surface, which lowers the final quality of your project.

Keep in mind that most primers have properties similar to epoxy. Thus, they will also form permanent drips on the surface if you don’t smoothen them in time. Make sure you work slowly and patiently to prevent this from happening.

3) Epoxy

You’ll naturally need a good epoxy product to carry out your project successfully. While this step may feel intuitive, there are several things you need to consider.

Perhaps the most important factor to keep in mind is the type of epoxy. These generally come in two forms.

The first one is a single-part epoxy resin. Single-part polymers dry naturally once you apply them, which makes them much easier to handle. However, single-part epoxy resins are less durable. We recommend these for small projects where the quality of the final coat isn’t as important.

One advantage of single-part epoxies is that they dry slower.

The other type is the two-part epoxy resin. As the name suggests, two-part epoxies consist of two components – the coat itself and a hardener. In this case, you must mix the two before you apply them to a wall.

Two-part epoxies are generally much more durable. The hardener triggers a cross-linking reaction during which the polymer subunits form chemical bonds. The final product is thus much more long-lasting.

However, these can be tricky to apply – you have to mix the two parts before you can use the product. Once you combine them, you only have a few minutes before the epoxy dries. This can be stressful, especially if you’ve never used epoxy before.

4) Sander

Whether you need this tool depends on what wall you’re dealing with. If it’s smooth, you can probably make do without this tool. But if it’s textured, you will certainly need a sander.

Textures form a barrier for epoxy, causing it to stick less in some places. This results in a poor finish. You generally want to sand the surface to ensure your epoxy sticks to it evenly.

5) Protection for your furniture

If you’re applying epoxy to a brand-new room, you likely have nothing to worry about. But what if you’re refurbishing an existing one? In this case, you have to look out for features such as furniture and window frames.

Thus, you’ll need to cover these surfaces with something else while you work. We recommend using a combination of masking tape and a plastic sheet. You can use the masking tape to protect thin frames. Conversely, use plastic sheets to cover tables, chairs, and other pieces of furniture.

6) Mixing container

You only need this tool if you’re using a two-part epoxy (which we strongly recommend – it’s more durable). You’ll need something in which you can mix the epoxy and the hardener. Although most products come with a container, these are usually small. We suggest using a bucket that you don’t need for anything else.

How to apply epoxy to a vertical surface – 6 simple steps

1) Clean the vertical wall of dirt

The first thing you must do is clean the wall. Dirt and dust increase the wall’s surface area, resulting in poor adhesion of the epoxy.

2) Seal bigger dents and imperfections

Dirt isn’t the only thing that can ruin your epoxy project. Although the coat can fill out small holes just fine, it won’t stick well to larger ones. Thus, you’ll need to fill them out separately. We recommend using a sealing compound designed specifically for this job.

If you skip this step, the epoxy may crack over time, and you will be left with dents in your wall. This lowers the visual appeal of your project. But more importantly, the cracks can spread over the rest of your epoxy wall as well.

3) Place plastic covers over your furniture

Before you start working, make sure you cover your furniture. Doing so will protect it from sawdust and epoxy.

4) Sand the wall (if textured)

Most epoxy products stick best to smooth surfaces. However, many walls are rough and textured, especially if they’re new. If you attempt to apply the epoxy on them, it won’t stick properly. We suggest using a sander with a vacuum to minimize the amount of dust you create.

If you’re working on a smooth surface, you can skip this step.

5) Add the primer

Using a primer is an optional step. However, we strongly recommend using one. It will fill out the smaller dents in the wall, resulting in a much better finish. Although it is an extra expense, it’s well worth the money.

If you’re using a two-part primer, make sure you mix it first.

6) Apply the epoxy itself

You can now apply the epoxy resin. Gently spread it across the surface using a foam roller. Apply it in thin layers. This will minimize the drips and make your job a lot easier. Work slowly until you cover the entire area.

Don’t forget to mix the epoxy with a hardener if you’re using a two-part product.

Our final thoughts on applying epoxy to vertical walls

Epoxy is a durable polymer used in both industrial and residential settings. Its main advantages are affordability and ease of use. But while it works flawlessly for horizontal surfaces such as floors, it can be tough to apply to walls.

Since epoxy is self-leveling, it will continuously drip down the wall because of gravity. This can lead to an ugly, textured surface. To prevent it, you’ll need to apply it in several thin layers.

We recommend using a foam roller since it is much easier to control than a brush. You should additionally use a primer to achieve the smoothest finish possible.

- Can You Unmix Paint: Techniques, Consequences, Alternatives - February 23, 2024

- Does Primer Need to be Mixed? Effective Primer Application - February 22, 2024

- How to Make Old Paint Usable Again: Retrieving and Preserving Paint - February 21, 2024