You are likely to find a Polycrylic wood preservative in most stores. However, without prior knowledge of its existence and uses, you might forego it for products that you know or might have heard about. When the time comes to try it out, you are slapped with the reality that it comes as both a gloss and semi-gloss. This will have you leave without making a purchase.

However, in the back of your mind, you know your wooden surfaces are begging for it.

Failure to protect wood will have you finding replacements faster than you might expect. It will also leave you in a financial hole, especially when you spend without prior budgeting. Those who try preserving their wooden surfaces go for cheap or homemade products.

Others would rather leave wooden surfaces in their natural element as any extra expense feels like a load. Once you decide to take a Polycrylic paint home, you need to only leave the right one for your surface. To help you make that pick, we shall address the following:

- The Notable Differences in both

- When to Use One Over the Other

- When You can combine Both

- Problems You Are Likely to Encounter When Using Either

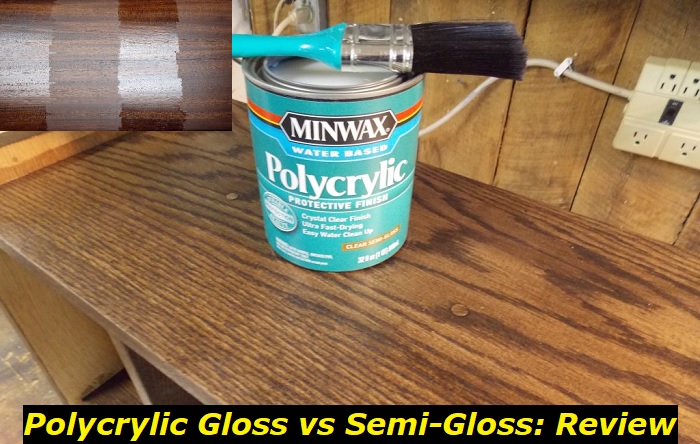

What Is Polycrylic?

This top coat is applied to wood to help it last longer without losing its natural look. This water-based coat’s primary contents include hydrated silica, Isopropanol, butoxyethanol, and Dimethyl ether. These solvents are mixed in different compositions to make the final product.

The highest concentration is Dimethyl ether, which takes about 35% of the total composition. The least used product is Hydrated Silica at 1% of the entire composition. However, some manufacturers have found ways to use different components or even create their compositions, and those concentration percentages might vary.

Major Similarities Between Polycrylic Semi-Gloss and Gloss

1) Non-Toxic

Previously, many people looking to protect wooded surfaces would go for engine oil. Others would go for creosotes. This became a cause for concern due to their toxic nature and effect on the environment. The production of Polycrylic, whether gloss or semi-gloss, has reduced the toxins released when looking to preserve the wood. The water-based preservative does not contain VOCs or Carcinogenic traits in it.

2) Non-Yellowing

Polycrylic is a clear coat and does not turn yellow over time. Most top coats in the market turn yellow, leaving the surface slightly different from before. They help the surface retain its natural appearance, and where paint is involved, it ensures it retains its original color.

3) Stain Resistance

Both are designed to resist staining. The little gloss on each ensures they can keep dirt at bay for as long as they can. Stains leave a surface looking weird, dirty, and abandoned. Additionally, it creates room for bacteria, fungi, and mold to grow.

4) Water Proof

Water damages wood within minutes after contact. Once wood soaks in water, it can rot or crack. Rotten or cracked wood becomes a weak link in building and even as a structure. Failure to spot it on time can lead to massive damage. These damages are not only expensive to replace, but they are also a health risk and a catastrophic accident waiting to happen. Both gloss and semi-gloss Polycrylic are waterproof, ensuring no water or moisture gets to the wood.

Major Differences between Polycrylic Semi-Gloss and Gloss

1) Sheen

This is crucial and essential when picking a gloss or semi-gloss Polycrylic. The variation found between them is achieved by varying the ingredients used. It is tricky since most people do not know what to look for. It also determines your product’s final look, and you cannot afford to mess with such.

Those with a better understanding of the components used will quickly look for the presence and concentration of resin and pigmentation. The higher the resin or varnish concentration, the glossier the outcome and vice versa.

Polycrylic gloss is shinier and more reflective when used on a surface. When light hits it, it bounces right back through reflection. Despite being a clear coat, it affects the surface paint color depending on the angle you look at it.

Semi-gloss polyclinic, on the other hand, appears dull and matte-like. When applied on surfaces, it does not glow but tends to soak in the wooden surface and appear more natural. It is also non-reflective and tends to absorb some of the light hitting it.

2) Surfaces Applied

Despite both being Polycrylic, each has surfaces it accentuates more than the other does. Semi-gloss, when applied, leaves a beautiful matte effect. This keeps the space looking new and beautiful for longer.

It is ideal for indoor surfaces and ceilings since it is not reflective. Reflective surfaces can cause eye irritation, confusion, and even partial blindness when exposed to light. It is also ideal for surfaces with little to no traffic.

You can also consider using it for rough surfaces and places with high moisture levels and grime, such as bathrooms and kitchens. It does not stain easily, and it is easy to clean. Dust and dirt are ever-present, and cleaning is such an uphill task. You can also apply it to conceal the imperfections on dented surfaces, making it pop. The best thing about it is that you can easily do touch-ups without ruining the previous paint or scraping it off. Polycrylic gloss is best suited in places with high traffic. It is water- and dust-resistant, making it ideal for spaces such as bathrooms and kitchens. It gives a sleek contemporary feel, and it can be used to create the illusion of large spaces.

3) Cost

Gloss paint costs more than a semi-gloss one. This is because a lot more work goes into the production of glossy paint. It also carries more ingredients than the semi-gloss one making it costly.

Its application process is also slightly longer; one mishap would have you redo the whole process. However, it is the toughest and amongst the most durable wood preservatives on the market today. Semi-gloss is relatively cheaper than gloss Polycrylic.

The downside to this is that it wears off easily and requires touch-ups every so often. However, when it comes to matters of price, many things have to be factored in, such as the size of the surface to be painted.

The larger the surface, the more paint is utilized, and vice versa. However, some manufacturers sell both at the same price. Holding everything else constant means that one type rakes in more than the other.

The Application Process: Similarities and Differences

Similarities

Both should be applied on clean surfaces and, where possible, sanded ones. This will help create uniformity in the paint and notice any other surface problems beforehand. However, some manufacturers now produce primers that do not require sanding. Read the manufacturer’s instructions to see where you stand with yours.

You should also use good quality brushes to ensure you get even strokes and distribution of the paint. Let each layer of product dry first before applying a subsequent one. Sand between these layers creates uniformity and preps the surface for adhesion, as smooth paint is hard to work with. Wipe any streaks to avoid bumps and air bubbles between layers.

For both, you get the option of using a brush or a spray. Before applying any layer of semi-gloss or gloss Polycrylic, assemble all materials needed. This helps you save time, and while at it, avoid having dry paint before it is even well spread.

When applying paint, use long strokes and follow the grain. Push your strokes past the surface to reduce visible brush marks. Finally, apply a thin layer to ensure you control each layer’s thickness and spreading capabilities.

Differences

- As a Base Coat

Semi-gloss Polycrylic can be used as a base coat to seal the wood before paint is applied. Sealing the wood helps ensure no moisture, animals, or bacteria attacks. At this point, no one is going after smoothness or sleekness. All efforts are focused on creating a foundation.

When perfectly done, your wooden surface will last for decades or even centuries. Gloss Polycrylic can give mixed results when used as a base coat.

Due to its gloss and hard texture, it might require more sanding time to increase the texture needed for paint to adhere once applied. It would also increase the chances of an uneven and inconsistent surface as it does not cover nor hide imperfect surfaces.

- As a Top Coat

Gloss Polycrylic is the perfect go-to topcoat due to its sleek glossy nature. It can easily transform your surface when applied correctly. It also forms a tough exterior that prevents external attacks on the surface.

Semi-gloss can also be used as a topcoat, but it would give different results. First, it does not form a tough exterior and would need regular touch-ups for maximum protection. It is also prone to staining, leaving you at a loss for cleaning and regularly scrubbing to keep it clean.

Conclusion

Polycrylic is an excellent preservative that would bestow the natural look of any wood surface. However, getting the correct one guarantees this. You do not need skills to apply it, making it a go-to option for DIYers. Take that first leap and try it out. You never know – it might be all your surfaces ever needed all along.

- Can You Unmix Paint: Techniques, Consequences, Alternatives - February 23, 2024

- Does Primer Need to be Mixed? Effective Primer Application - February 22, 2024

- How to Make Old Paint Usable Again: Retrieving and Preserving Paint - February 21, 2024