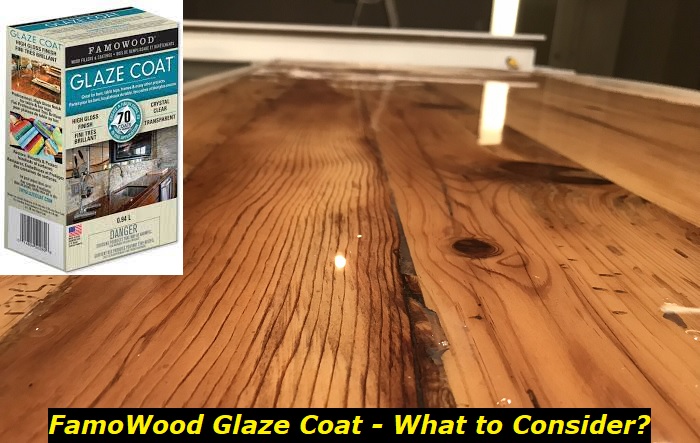

Famowood Glaze Coat is an epoxy coating that the American company Eclectic manufactures. It is a high gloss two-part epoxy resin product for home and craft projects. It is a reliable and strong product that protects surfaces you apply it to. Popular amongst professionals and do-it-yourself enthusiasts, Famowood Glaze Coat’s application stretches from preserving artwork and photographs to coating tables and countertops. As a pour-on epoxy coating, Famowood Glaze Coat provides a durable, corrosion-resistant layer to various surfaces.

To get the best finish, reading and following instructions are essential. This guide will expose you to tools, instructions, and considerations for using Famowood Glaze Coat.

Tools Required for Applying Famowood Glaze Coat

There are some tools needed to apply the Famowood epoxy resin. Having these tools will help ensure the successful use of Famowood Glaze Coating. The tools include:

- Measuring cups – you will need at least three paper or plastic cups or buckets marked with volume measurements. Famowood Glaze Coat is a two-part epoxy resin that needs precise measuring of resin and hardener.

- Mixing containers – you will need different containers for the hardener and resin.

- Stir sticks or paint paddles – to thoroughly mix resin and hardener, you will need a straight-edged stir stick or paint paddle.

- Plastic spreader or notched trowel – you will need one to spread the Famowood Glaze Coat on the surface after mixing.

- Disposable Foam brushes, paint brushes, or rollers – we recommend using foam brushes for applying Famowood Glaze Coat because of their ease of use and efficiency in creating a smooth and even finish. You can also use paintbrushes and rollers.

- Heat gun, butane/propane torch, or blow dryer – these are vital for removing air bubbles that may form as you mix and apply the coat.

- Eye protection, Gloves, and protective clothing – Famowood Glaze Coat is an epoxy resin with chemicals that can affect your health when you come in contact with it. So, we advise using protective clothing, eye protection, and gloves when dealing with it. The gloves can be latex vinyl or chemical-resistant neoprene gloves.

- Carpenters level – Famowood Glaze Coat is self-leveling, so it is vital to use a leveler to level out the surface before applying the resin.

- Masking or painter’s tape – This is necessary to protect nearby surfaces to which you do not want to apply the coat.

Instructions For Using Famowood Glaze Coat

There are a number of steps you should take when applying Famowood Glaze Coat to any surface. Here we will outline each step and explain the procedure to you. Below is a list of instructions for using the Famowood Glaze Coat.

1) Prepare The Surface

Before mixing and applying Famowood Glaze Coat, you must clean whatever surface you want to coat. The surface must be clean of debris, dust, wax, grease, or oil. Also, the surface must be dry before you begin work on it. Additionally, due to its self-leveling property, you should keep the surface free of bumps or dents. You can level or sand the surface if necessary.

2) Wear Protective Clothing

Famowood Glaze Coat has chemicals that can be harmful. Before you begin the next step, wear protective gear, including gloves, eye protection, and protective clothing.

3) Mix

Famowood Glaze Coat is a two-part epoxy. The two parts are the resin and hardener. You will need to mix both of them thoroughly before use. Below are the steps:

- Pour the measured hardener and resin into two disposable, clean, and unwaxed mixing containers. The correct mix ratio for the hardener and resin is 1:1. Only mix what you can spread at one time.

- Pour the accurately measured hardener from its container into the mixing container with the mixed resin.

- Use a clean stir stick or paint paddle to stir the mixture for 6 minutes thoroughly. Your revolutions as you stir should be gentle and steady. Make sure the stick reaches the sides and bottom of the container while you mix. Do not use a mechanical or power-driven tool to mix the coating because doing this will create excessive bubbles and cause quick thickening of the materials.

- Pour the hardener-resin mix into a different clean mixing container and stir for another six minutes or until the temperature reaches 90 degrees Fahrenheit (90 °F).

The mixing instructions are fundamental, and you should follow them as described. As you mix, some air bubbles can show up. You can remove them in the next step. Additionally, at no point should you allow the mixture to sit. Allowing the mixture to sit or settle will cause it to harden and overheat and become hot to the touch.

4) Pour The Coat

Famowood Glaze Coat cannot sit as the mix will begin to harden 15 to 20 minutes after mixing. So, once you have completed the previous step:

- Pour the Famowood Glaze Coat mix into the intended surface’s center immediately.

- Spread the mix from the center to the rest of the surface with a squeegee, plastic spreader, or notched trowel or brush. Use a combing method to spread the mix over the surface. Notched squeegees and trowels work better for large surfaces like bar tops and tables. Avoid overspreading; otherwise, the mixture will not self-level during curing. Pour only as much of the mix as you can spread.

5) Remove Bubbles

During the mixing process, it is normal for bubbles to occur. Usually, at the initial pour, most air bubbles rise to the surface and disappear. However, because of the thickness of the Famowood Glaze Coat, you may need to perform additional steps to speed up the process and remove all bubbles. Remove the bubbles when the surface is still wet, or else the bubbles will emerge as dimples on the surface once fully cured. To remove bubbles:

- Blow on the bubbles gently to force them out using a blow dryer.

- Use a heat gun or small handheld torch (butane or propane) to remove bubbles on larger surfaces. Do not allow the flames to come closer than 6 – 8 inches to the surface.

- Move the torch over the glazed surface until the surface is without bubbles. Do not apply flame in only one area.

6) Curing

Curing occurs when the glaze coat dries to the touch. A Famowood Glaze Coat will take around 72 hours to cure fully. The coat and surface should be around the same temperature, ideally between 70 and 80°F. Warmer temperatures may lead to faster curing times.

You can add another coat 4 to 5 hours after the initial application. However, for a third coat or more, leave it to cure for up to 24 hours and not more than 48 hours before you add another one.

7) Clean Up

Use alcohol or acetone to clean up your tools and work area. You can only clean Famowood Glaze Coat while it is in liquid form. If you let it cure or harden, you must use a paint remover or sanding to clean it. Also, wash your skin thoroughly with soap and water after completing the project.

Things To Consider When Using Famowood Glaze Coat

Besides the instructions and steps needed to mix and apply Famowood Glaze Coat, there are other things you should keep in mind. We discuss them below.

1) Safety

Above an excellent finish is your health and safety. Famowood is a chemical product that can have negative consequences if you do not observe care and precaution.

- Wear gloves and protective clothing before you apply the resin to prevent skin irritation.

- Ensure your working area has adequate ventilation and avoid inhaling fumes and vapors.

- Eye protection is also needed because epoxy resins may cause eye irritation. Even worse, the hardener can cause eye damage.

- If the resin or hardener ever gets in your eyes, rinse it gently with lots of water for up to 15 minutes, and if it comes in contact with your skin, wash it with soap and water. If any of the symptoms continue, seek medical help. Keep this product away from children.

- Do not apply Famowood Glaze Coat on surfaces that may come into close contact with drinking water, food, or animals.

2) Coverage

There are varying sizes of Famowood Glaze Coat. Thus, you should get an adequate amount for your project. The coating thickness determines how much you need to purchase. Based on a 1/16 coat thickness, a pint of Famowood Glaze Coat will cover up to 3.2 square feet, while a quart will cover 6.4 square feet. A gallon should be enough for 25.6 square feet.

3) Compatibility

While Famowood Glaze Coat is compatible with several surfaces, including stone, wood, and ceramic, test it on a small area before applying it to a large surface to ensure it will adhere correctly.

Also, since most woods are porous, seal the surface with a sealant before you start the main pouring procedure. Furthermore, do not apply Famowood Glaze Coat to surfaces that will come into direct contact with sunlight. Additionally, do not apply on floors, hot surfaces like cookware, or surfaces directly exposed to sunlight.

4) Maintenance

Completing the application of Famowood Glaze Coat is not the end of your work. You must continue to maintain it to keep it durable and in fine condition. Do not use abrasive cleaners or sharp objects on the surface. Also, wipe spills and stains on the coated surface as soon as they occur.

Conclusion

Famowood is a versatile, durable product used on various surfaces and projects. But you must follow instructions and use the correct tools for the best results. We have listed considerations that should help you regarding compatibility, coverage, and safety when applying Famowood Glaze Coat. You must also prioritize maintenance of the Famowood Glaze Coated surface to ensure it lasts long.

- Can You Unmix Paint: Techniques, Consequences, Alternatives - February 23, 2024

- Does Primer Need to be Mixed? Effective Primer Application - February 22, 2024

- How to Make Old Paint Usable Again: Retrieving and Preserving Paint - February 21, 2024