Wood gets damaged over an extended period. It could result from household accidents or wear and tear. More often than not, there’s no need to remove the wooden furniture pieces because you can consider a simple wood repair.

A typical wood filler can salvage the wood chips in your furniture. However, for exterior wooden maintenance, you will require something to hold up stronger.

Epoxy is a standard wood filler used to repair wooden materials. It comes in various forms. Many epoxy products contain polyester that may leave the wood repair fragile and susceptible to other damages due to rot.

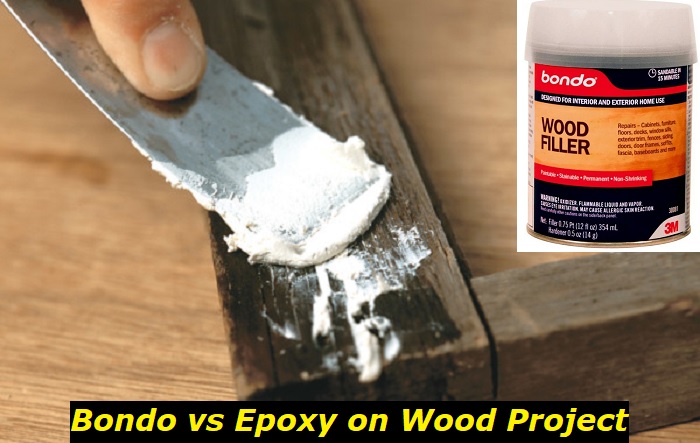

Numerous formulations make epoxy compounds compatible with glass, wood, concrete, stone, and other materials. Bondo is a product made for auto body repairs, but it is also a great wood filler. It is a remedy product used to replace rotted-out door sills and windows.

Bondo gives a rigid structure to chunked or chipped corners of the wood. It is a popular product used in woodworking. In this article, we will delve into the things you should know before choosing Bondo or Epoxy for your woodwork project.

What is Bondo?

Bondo is an excellent product initially made to patch vehicle damage, but it suddenly started being used on wood. Bondo brand has been available for decades, tackling the most complex repairs and restorations. Bondo products offer a combination of undercoatings, putties, and glazes for several applications, including household, automotive, hobby, marine, and so much more.

Bondo products can be used to repair and restore wood, aluminum, metal, brick, stone, and fiberglass. Bondo all-purpose putty is a versatile rigid filler for preparing interior and exterior surfaces around the home and workspace.

It is a fast-curing filler that lets you make a high-quality and long-lasting repair to wood, metal, Drywall, concrete, and Mansory. It is thicker than most Bondo products and excellent for repairing vertical surfaces like walls, sliding, and doors.

How to apply Bondo body filler on wood

The early step in using a Bondo body filler is gathering your tools and ensuring that it is everything required for repairing scratches and chips. Some of the tools needed for using Bondo body filler on wood include;

- Bondo spreaders

- Body shapers

- Stud gun

- Body filler

- Sander

- Paintless dent repair kit

- 80-grit abrasive sheet

- Mixing board

- Patch metal

- Mesh

- Dent removal tools

The steps to follow include:

Step 1

- Prepare the surface, and ensure it is free of dirt, grime, wax, or any other material that might prevent it from sticking. Be aware that you can utilize a lint-free cloth to wipe down with an adhesive remover.

- If the surface is painted, it should undergo sanding since the filler does not adhere well to paint and humid surfaces

Step 2

- Mix the filler following the instructions of the product. You can mix the product with your spreader and mixing board. Do this efficiently to make the hardener be introduced entirely.

- After mixing, use the spreader to coat the damaged area entirely and avoid overfilling. Apply the first filler coat firmly so it sticks well to the surface.

- To achieve a seamless transition, fill the damage and broaden the putty around the surrounding area. This will enable you to sand it out when it dries.

Step 3

- Smooth out the filler by sanding. Use an 80-grit abrasive sheet to smoothen out the dried filler.

- If you oversand a spot on the entire damaged area, you should reapply another coat of the filler and wait until it has dried thoroughly before you continue.

- You should sand the surface until it is smooth and leveled with the rest of the area. Feather-edging around the rim of the damaged surface will blend seamlessly with the rest of the surroundings.

- You can use a 180-grit abrasive sheet to featheredge. It will remove lines and scratches from the surface.

Step 4

- When the surface gets smooth, it gets evened out with the rest of the surface body. You can apply primer, topcoat, and clear coat.

What is Epoxy?

Epoxy is an inorganic compound that is a type of polymer and consists of large molecules of repeating subunits. The molecular structure of this polymer gives it a high elasticity and toughness. Epoxy fillers make epoxy solidified for several purposes, asides from wetting or coating out fiberglass.

You can use epoxy fillers for several applications, such as gap filling, adhesive bonding, filleting, and fairing. You do not need to buy different resins for each application.

Epoxy fillers are used in woodworking, boat building, repairs, and household projects. It is safe to make your own thickened epoxy, although several pre-thickened products can be used for several applications.

Types of Epoxy fillers

Some epoxy fillers are more accessible to sand and make better subframe compounds, while some are better for creating structural adhesives. It is very suitable to mix epoxy fillers to make the mixture more productive.

Colloidal silica

This is a fine white powder that is a Silica thickener. It can be mixed into epoxy, depending on the amount to get the consistency needed to fill gaps, glue items together, create structural fillets and fill holes. Colloidal silica makes an epoxy putty to prevent sagging. It is known as the ideal structural epoxy filler.

Microballoons

Microballons are lightweight epoxy fillers that consist of plastic microspheres mixed with epoxy to form a lightweight subframe compound that is easy to shape and sand. They can be combined with colloidal silica to prevent the mixture from sagging on overhead and vertical surfaces.

Milled glass fiber

Milled glass fiber is made with precisely ground fiberglass strands that thicken epoxy to fill thin gaps or create delicate fillets. This type of epoxy filler offers maximum resistance to cracking.

It can form an uneven or coarse surface when thoroughly cured. It is not to be used for applications that require sanding. Colloidal silica can be mixed with milled glass fiber to prevent sagging.

Wood flour

Wood flour is a fine resin filler made of pulverized wood. When mixed with epoxy, it creates a rigid adhesive. It is ideal for wooden boat construction because it adds a wood color undertone to the epoxy mixture. Wood flour can be added to colossal silica to keep it from sagging, and it can be combined with microballoons to make it easier to sand.

Advantages of using Epoxy on your woodworking projects

- Strength and durability

Due to the polymeric structure of epoxy, it creates an incredible stronghold that can withstand high temperatures, and it is also water-repellent.

- Water resistance

Most epoxy products are waterproof, especially when hardened. Some Epoxy products are designed to cure quickly, even when exposed to water and other liquids.

- Compatibility

Epoxy adhesives can bind to a vast collection of several materials, while some bonds are limited in their use. Epoxy resins can offer greater flexibility even on porous surfaces.

- Curing time

The curing period for Epoxy varies, although some fast-acting ones can functionally cure within an hour.

Disadvantages of Epoxy

- It can be hazardous

Epoxy fumes can be pretty toxic to humans and animals. It is recommended to use it in well-ventilated spaces. Epoxy offers the best result when applied on dry surfaces.

- It has a complicated application

A two-part epoxy requires mixing it with two different substances by an application system or by hand. Most adhesives are easier to apply, and the resulting bond will be sufficient.

Advantages of using Bondo filler

Bondo is used in many interior and exterior applications. The best way to use it is by applying layers that aren’t too thick to form a build-up. You should also avoid using wood to fill up voids. Some of the benefits of Bondo include;

- It is easier to apply

Bondo products are easy to apply to several surfaces. They do not require many tools for the application.

- It is cost-effective

Bondo is cheaper than most wood fillers; it is one of the most common reasons it is used by many.

Disadvantages of Bondo

- It covers the wood’s natural beauty

When Bondo is used as a wood filler, it can cover the natural markings and color of the wood. This means that priming and painting of the surface will be required, which might be undesirable if you want a natural wood look.

- It is hazardous

The fumes of Bondo can be pretty toxic and intense. You can notice this when you open a can of Bondo. It is recommended to be adequately protected when using it because it can cause burns when it gets in contact with your skin.

Tips when using Wood fillers on woodworking projects

- It’s very necessary to have the correct ratios when mixing hardeners into a Bondo or Epoxy putty.

- Use a plastic spreader or go for a metal spreader since it is more durable and creates a more defined edge, and lasts longer.

- You should have a thinner available if the putty is drying too fast.

- Avoid using cardboard as a mixing palette because it will mess with the chemical components of the mix, and it is also absorbent.

- You can use electric torches or a heat lamp to dry the surface if you repair components in wet or cold conditions.

- Can You Unmix Paint: Techniques, Consequences, Alternatives - February 23, 2024

- Does Primer Need to be Mixed? Effective Primer Application - February 22, 2024

- How to Make Old Paint Usable Again: Retrieving and Preserving Paint - February 21, 2024